Concrete Molds & Services

Columbia's concrete and paver molds have raised the bar for years and are known for their quality, fit, and finish.

What is a Concrete Mold?

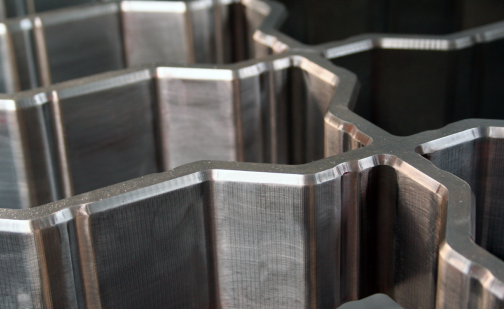

A concrete mold is a steel grid that forms concrete mix into stones of a desired shape, usually producing multiple stones in one cycle. Stones can be blocks, pavers, hardscapes, etc.

Concrete Mold Capabilities

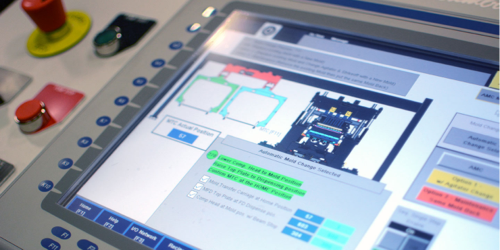

From products or services to technical tips and assembly instructions, we want you to get the most out of your concrete molds as possible.

Mold Product Catalog

Our hardworking molds set the standard in the industry by producing perfect products for countless cycles.

Online Mold Parts Ordering

A personalized online store offers a quick and intuitive way to order the parts you need to keep your plant up and running.

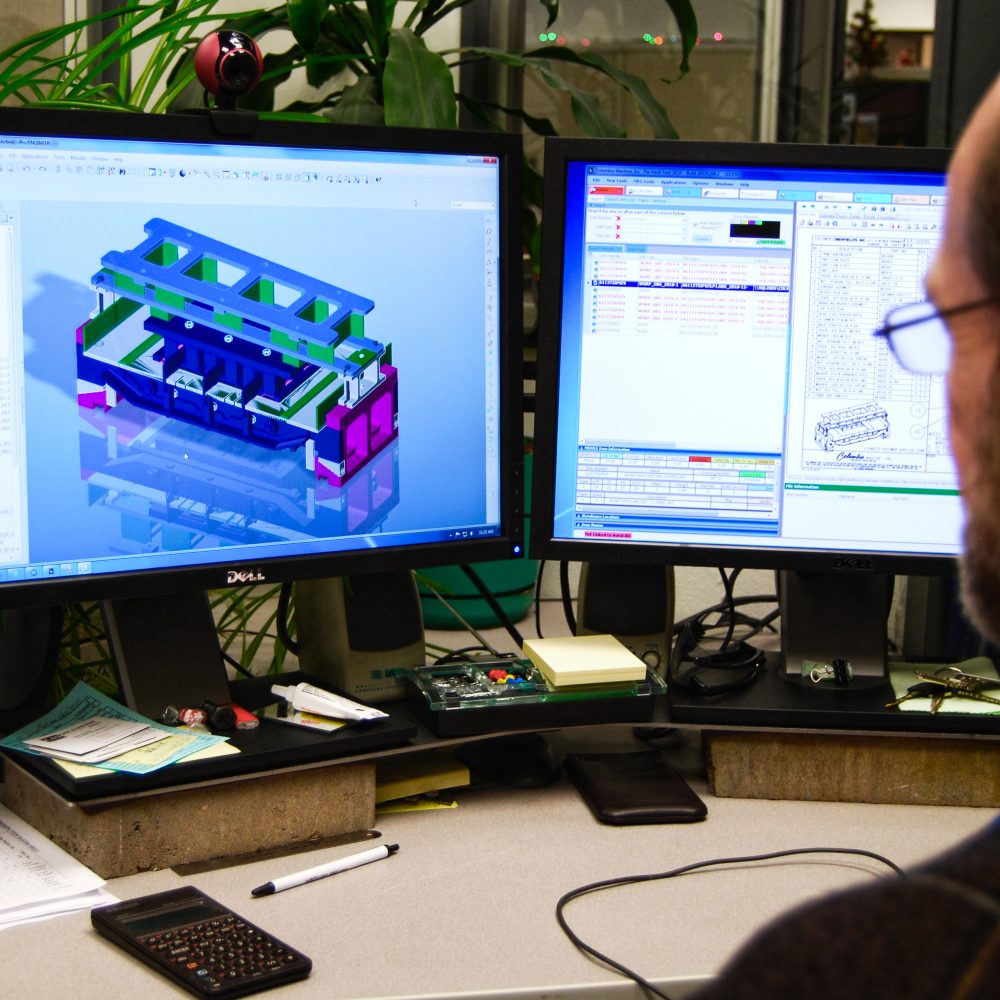

Engineering

Columbia’s 3D parametric CAD system allows us to design concrete molds for the most complex products and shapes our industry demands. From the most basic CMU to precision pavers and textured surfaces, our experienced engineering staff has the tools and knowledge to exceed your expectations.

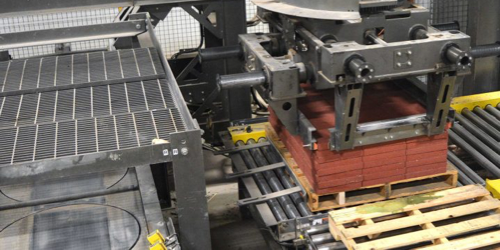

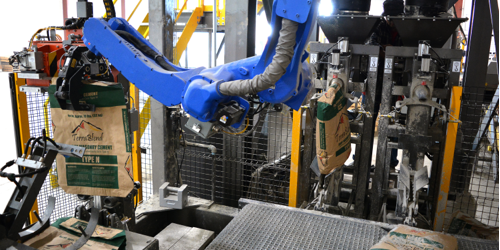

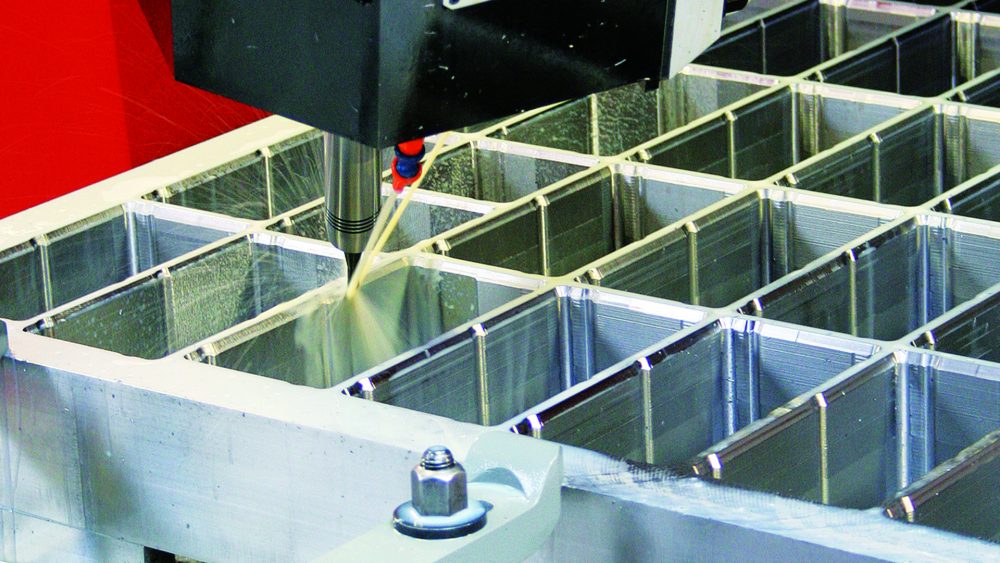

Manufacturing

From basic parts to complex concrete molds solutions, our state of the art CNC equipment and robotic fabrication capabilities provides complete concrete mold solutions for your production needs. Our Machine Shop has some impressive capabilities including in-house heat treating, surface grinding, and full concrete mold assembly testing to name a few.

Prototyping & Scanning

We can recreate prototype stone products to allow customers to manipulate possible stone designs for pattern variations and applications.

Concrete Mold Research & Development

Our seasoned team is here to assist you with new products, changes to current equipment, technical support for concrete molds, and any production questions you may have. Columbia offers a free sieve analysis to determine a wide range of factors: strength, texture, porosity, workability, availability.

Concrete Mold Repair & Rebuild

We repair and rebuild concrete molds for any machine, including Columbia and competitive concrete molds.

- All types of hard surface welding (tig, stainless, wire, etc.)

- Grinding/Machining

- Inspection & testing, post repair

- All work done in-house by skilled craftspeople

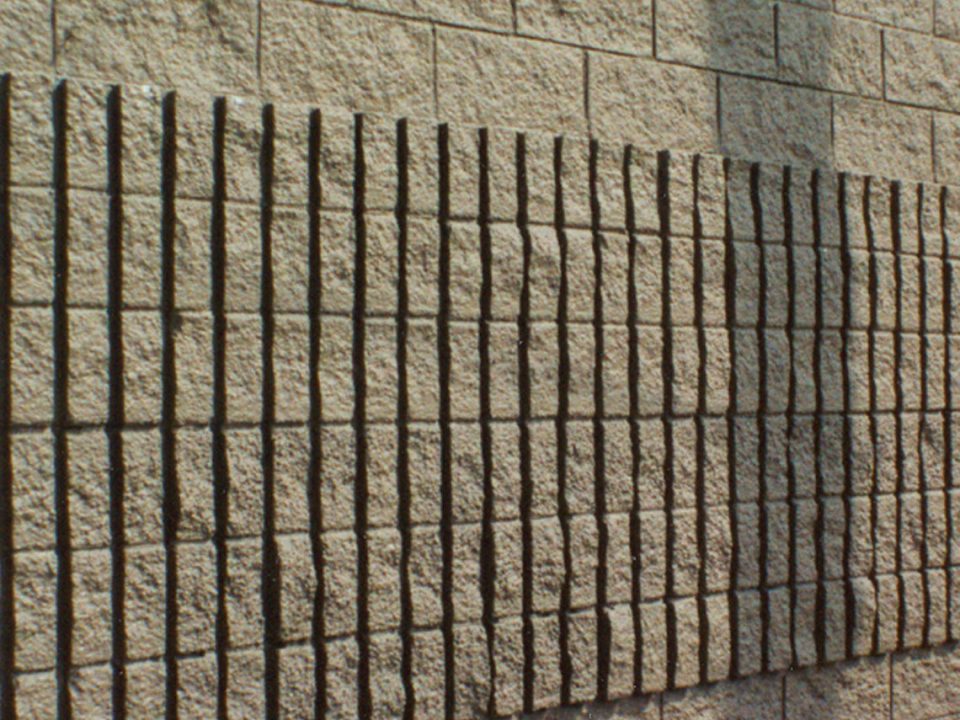

Concrete Products

Concrete molds add a new dimension, quite literally, to your concrete products lineup. They expand your capabilities by allowing you to offer products that look and perform beautifully and can be used for many different purposes. Whether it’s pavers, retaining wall, landscape, or masonry products, let us help you produce high quality products to meet your markets needs.

Paver Molds & Slab Catalog

Our hardworking concrete molds set the standard in the industry by producing perfect products for countless cycles.

Types Of Concrete Molds

Columbia concrete molds are engineered and designed for your production needs. Our line of D2P molds provide options you are looking for to control concrete mold costs and match your mold purchases to your true needs.

- Universal

- Premium

- Paver

- Articulating

- Big Board

- Non-Columbia Concrete Molds

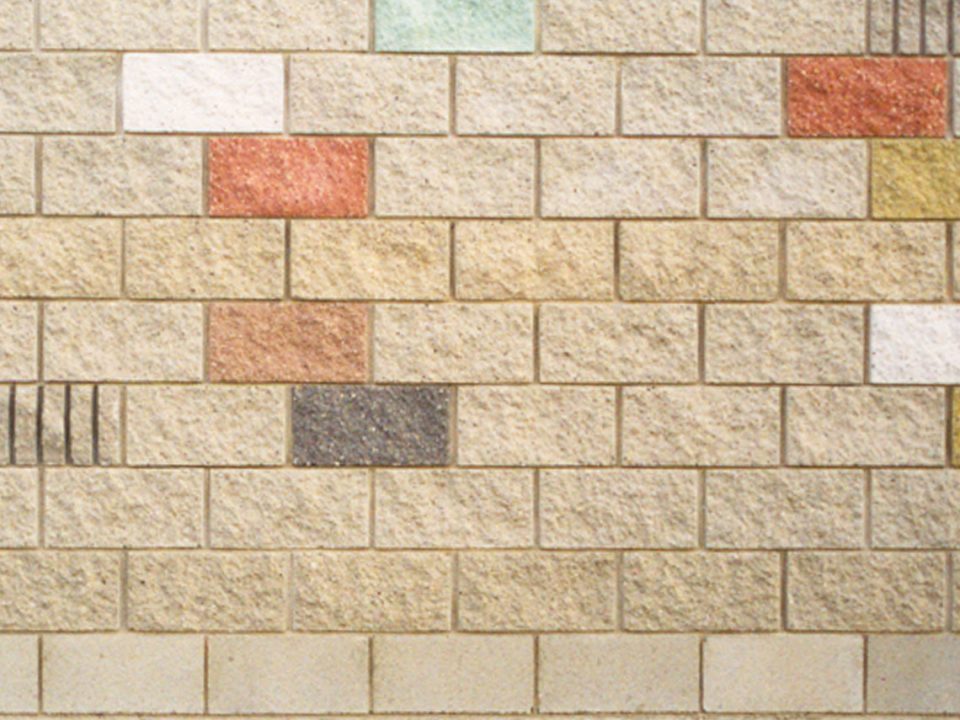

Custom Surface Textures

We understand surface textures add breadth and depth to your product line. With today’s software and scanning technology, we created some of our favorite organic surfaces that allow for a distinctive texture on the concrete molds and other products you create. In addition to our standard textures, send us your design and we can quickly provide customized surface samples.

Online Concrete Mold Parts Ordering

Browse and order concrete mold parts online using our e-commerce site. You can search based on the equipment you own, and easily order whatever parts you may need.

Order PartsConcrete Mold FAQs

Our engineering team designs the mold based on customer specifications. Then the design is sent to our production facility where multiple steel alloys are cut and heat treated to spec before being assembled by world class technicians.

Each mold is custom designed for a specific block machine and product. Simply mount the mold per your machine’s instructions and start making product!

Yes, invariably wear parts need to be replaced. For traditional block molds this can usually be done by simply ordering replacement wear parts. For larger molds, which are often made in a monoblock design, repair is usually possible and very economical at one of Columbia’s mold repair facilities.

Concrete Molds Resource Catalog

Find the parts you need to keep your plant running at peak performance.

We’re Ready To Help

For more information or questions on any of our concrete products solutions