Phoenix Paver

CUSTOMER PROFILE

Phoenix Paver was established in 2005. Increasing demand for high-quality pavers in the Phoenix Metropolitan area caught the attention of owners Jay Donkersloot and Bart Klopping.

With Jay’s business acumen and Bart’s industry talent, a successful partnership was born. In 2005 they purchased the property and plant from Jensen Patio Brick/Natural Stone, located just south of the Salt River in central Phoenix, Arizona.

That same year they assembled an all-star team to bring the vision to life. Rupp Consulting was hired to manage plant development. David Williams was drafted for his extensive experience in operations making pavers, and Carl Huffman Jr. was appointed to head up the sales division.

At the time, the plant had an old Flemming Eagle, a Columbia UL26 Pallet Handling System, and a Columbia Model 2 Cuber. With a desire to create innovative high-quality pavers, they purchased a new Columbia Model 16 Concrete Products Machine, Turmac Batching; which included a planetary mixer, Columbia Spectrumatic Color Blending System, and Columbia MBS Batching Controls. They refurbished the existing pallet handling system and the cuber, and then in 2006 set to work carving out a market niche using the small 18-1/2” x 26” pallet size to their advantage.

Despite the challenge of competing with other big board machines located in the general area, Phoenix Paver has defied expectations.

According to Operations Manager David Williams, whose experience ranges from big board machines to small pallet machines: “Our color blends are consistent on every single pallet from top to bottom. So, when a contractor is looking at a small job of say 200 square feet, the resulting blends layout in a finished installation consistently. Whereas often times with products made on a big board machine, larger, unnecessary quantities must be purchased to get an even distribution of random patterns.”

“The reasons we decided to go with Columbia originally was, familiarity, the equipment is easy to work on, maintenance costs are low, and we loved the heated head for making a tightly textured paver,” Williams said.

“Other advantages of the small pallet machine have been lower operating costs, good parts availability from Columbia, less downtime, and better height control. In my experience running big board machines, the biggest issue was consistent height control across the production pallet. With Columbia’s CVT vibration, the ability to maintain accurate height tolerance is unmatched in the industry,” said Williams.

When asked about the challenge of output on a small pallet versus a large board, Williams said: “We are able to make 25% of a layer per cycle, and cycle time is two for every one cycle on a big board machine, so we make 50% of a layer in the same amount of time, but with all things considered it has proven to be a comparative advantage.”

In the beginning, Phoenix Paver offered three sizes of pavers and two colors. Today they offer 24 sizes and 4 colors and continue to grow with the market. Integral to their success has been their signature color blends, achieved by using the Columbia Spectrumatic Color Blending System and MBS Batching Controls.

On September 20, 2011 business partner and friend, Bart Klopping passed away at the young age of 48. This dealt a serious blow to the Phoenix Paver team, but their resilience and determination allowed them to tread forward.

In 2014, realizing the success of his endeavor into the masonry industry, Mr. Donkersloot sought to expand again. With a solid team in place, he decided to select Columbia Machine as the equipment supplier for plant number two.

On February 9, 2015, Phoenix Paver’s new paver plant thundered to life. Due to its resounding success, the decision was made to replicate plant one built in 2005. The purpose was multi-functional: increase production capacity, while standardizing the equipment, molds, processes, and training. On day one, chosen employees moved into a new version of their old plant and were able to transition seamlessly.

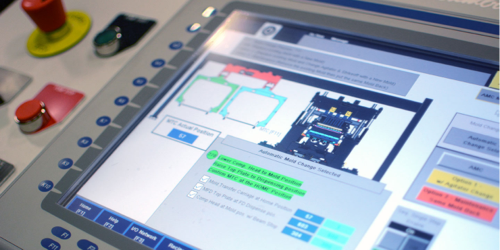

This new plant consists of an 1125 liter Planetary Mixer with 4 discharge doors, Spectrumatic Color Blending and MBS Batching Controls, which allows for the storage and creation for up to 40 product recipes.

With this system, Phoenix Paver creates their beautiful signature blends, such as Native, Tierra Norte, and Territorial. The quality and richness of the sharply defined colors replicate the surrounding natural landscape with reliable consistency.

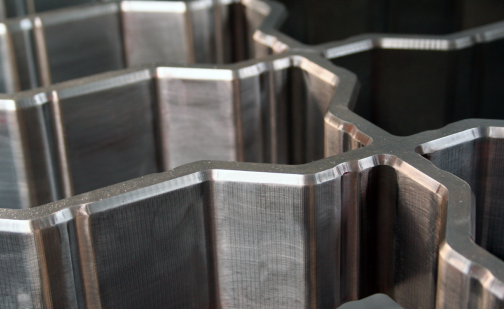

The concrete mix is then conveyed into the Model 16 HFH Concrete Products Machine, which forms the product using the industry-leading CVT vibration, ensuring uniform product density, accurate height tolerances, and extended mold life.

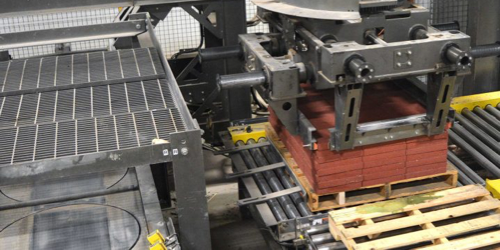

The production pallets are then transferred into racks with a UL26 Rack Loader and Unloader Pallet Handling System. The racks are transferred into kilns, and back to the rack conveyor by forklift.

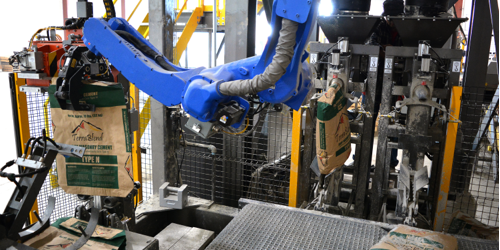

Cured product is conveyed downstream, with the option to be fed through a Columbia 1224 Concrete Product Splitter with Encoder, with roll-in/roll-out capability – or directly into the Columbia PSC 100, Semi-Automatic Cuber, with Pallet Dispenser. Cubes of product are then stretch wrapped on a Lantech Wrapper, and transferred into the yard by forklift. These products are either sold out the door, or staged for further processing.

At last count, this plant was operating with four employees on single, 10 hour shifts, 5 days per week, producing between 5,100 – 5,400 cycles of product per shift. Add to that, on the last two paver molds they were able to achieve wear life of 196,000 cycles and 207,000 cycles, respectively.

When asked about the future of Phoenix Paver, David said “we are currently at around 60% capacity and this number continues to grow every day. When we max out capacity, we plan to continue expanding.”

Phoenix Paver is the recipient of multiple architectural design awards and will be the host of the 2016 NCMA Virtual Tour for Columbia Machine.

Phoenix Paver guarantees the highest level of quality products and service to its customers, which is ultimately why they chose Columbia Machine as an equipment supplier.