Longleaf Packaging, LLC: Challenging Bagging Industry Standards

Working together, Longleaf Packaging and Columbia Machine, Inc. designed and constructed a new bagging facility to serve local contractors and the surrounding market.

Their 20,000 square-foot plant sits on 36 acres and houses an industry-leading, automated bagging facility, producing various weight valve bags as well as multiple sizes of bulk bags. This facility is capable of producing up to 30 tons of finished bagged goods an hour.

Working together, Longleaf Packaging and Columbia Machine, Inc. designed and constructed a new bagging facility to serve local contractors and the surrounding market. This plant showcases a material handling system with future expansion capabilities to store and manage wet sand and aggregate before drying. A 30-ton per hour rotatory dryer system runs the raw materials. Multiple dry storage holding silos house the dried product.

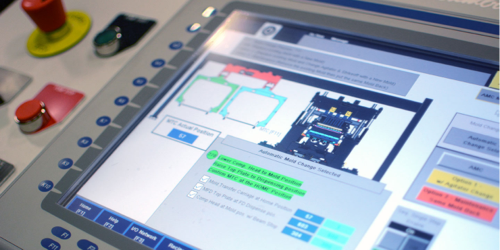

Columbia’s Batchmatic G2 batching controls handle all batching and mixing requirements for the plant. These controls store hundreds of programmed recipes for multiple product types, and its easy-to-use operator interface makes optimization of batching output and cycle times easy to monitor and adjust.

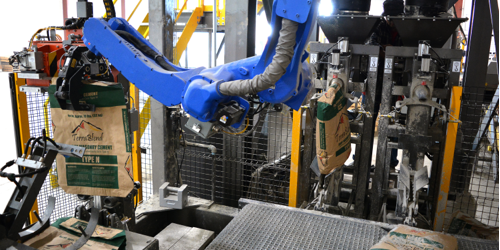

At the center of the blending plant is a 2250L counter-current, planetary mixer with dry-mix specific mixer features. Finished mixed materials are handled at the bulk bag filling station or by Columbia’s dual spout, model 201 PS Air Packer Station. Additionally, Columbia’s 401 Impeller Packer bags powders and cement.

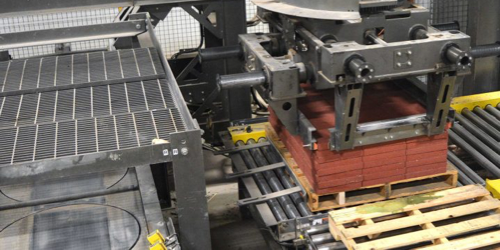

Columbia/Okura LLC installed a robotic palletizing system to transfer and stack finished products efficiently. This system conditions and palletizes bags at rates of up to 28 bags per minute. The reduced footprint, low maintenance, and high uptime made the robot an obvious choice to bookend the bagging line.

Columbia offers complete bag line solutions, from raw materials to finished products, and as exemplified by Longleaf Packaging’s new facility, Columbia is an expert in bagging systems.

Written for the Columbia Machine, Inc. Feed Drawer Publication, 2020.