WDL Group

Lead The Way

Bill Lewis, Founder of WD Lewis Limited.

WDL Concrete and the Red Dragon

In wonderful Wales, the home of renowned Welsh rugby, to the far West of the UK mainland, the red dragon is a symbol of tremendous pride & strength. Back in the 1750–1900 UK industrial revolution, heavy coal mining & blast furnace steel production once shaped & dominated this determined region. In 1807, the red dragon on a green mount was adopted in the Welsh national flag as the royal badge of Wales. In 1953, the motto Y Ddraig goch ddyry cychwyn (the red dragon leads the way’) was added, a line from the C15 poet Deio ab Ieuan Du.

Columbia are thrilled to announce WDL Group, a first-class, fully independent family business with an enviable reputation as the latest addition to our ever-growing population of specialist concrete product producers in the UK market. It is entirely fitting that the red dragon is prominently embedded in the WDL Group logo, and locals in South Wales would proudly confirm that WDL leads the way in uncompromising product quality and dependable customer service.

Joint-MD: Martin Lewis

Joint Managing Directed at WDL Group, with 5 decades of dedicated concrete products experience.

A Brief History of WDL Concrete.

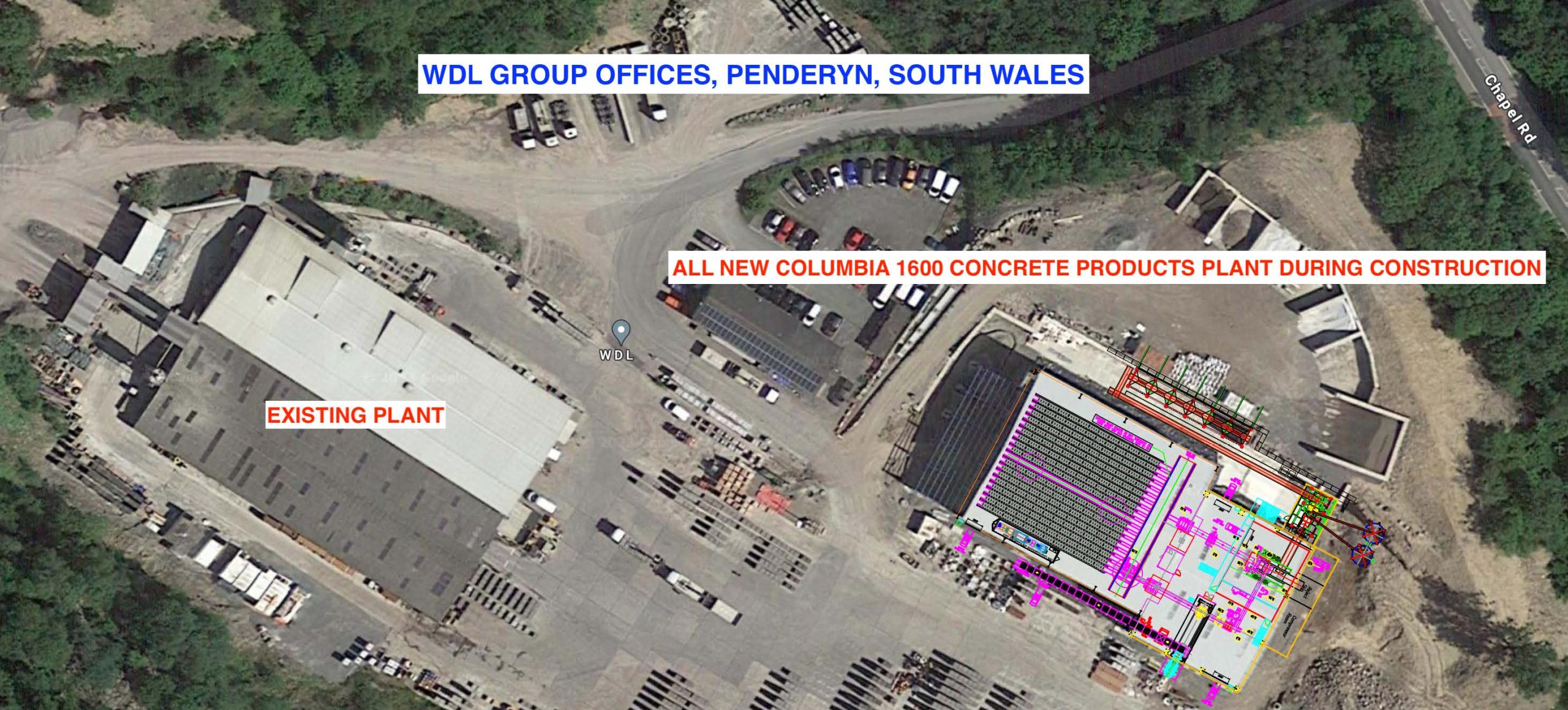

Situated on the edge of the village of Penderyn, skirting the southern boundary of the Brecon Beacons national park in the stunning Welsh valleys, WD Lewis celebrates over 50 years of hands-on experience since their establishment by Mr Bill Lewis in1972.

WDL Concrete produce & supply concrete products to both the domestic & commercial building industries with a diverse client base including major house builders, local authorities, private commercial customers, builders merchants & small traders. Large projects have included the Welsh national sports stadiums and many major retail parks.

WD Lewis was founded by Bill Lewis and began operating as a Civil Engineering contractor in the local area. Bill very sadly died in a tragic accident at work and the business was carried on by two of his sons. The group is now directed by brothers, Robert & Martin Lewis. Robert dedicates himself to the growth of WDL Contracting & WDL Homes while Martin concentrates on concrete products at WDL Concrete.

Cutting their teeth with ‘egg-layer’ machines, WDL soon evolved to static table vibration machines from Denmark. Martin and his extremely loyal and motivated team have always moved forward with the changing demands of their local market in offering a vast range of solid, cellular & hollow concrete products including dense & medium density block in standard and paint grade finishes, inert volcanic pumice insulation block, coursing block, dense aggregate midi block & rock face block. All concrete products are manufactured in strict accordance with European industry standards and relevant UK building regulations. At the Penderyn production site WDL always hold a significant level of stock so that cured block packs are immediately available, quickly loaded onto their own fresh fleet of distinctive bright red & silver livery trucks and out for delivery.

The Start of a Long-Term Partnership With Columbia.

In response to a growing market and with their next family generation now actively involved, Martin & Robert needed more high quality product. Planning permission was sought for an ‘all new’ 30,000 block/shift factory within the existing site and the search was now on for a reputable supplier.

Stephen Wilson, Columbia’s territory sales representative arranged visits for Martin and his team to the highly respected Columbia plants of Lignacite, S. Morris & Stowell in the UK. Martin also visited the Columbia team at the Bauma trade exhibition in Munich, Germany.

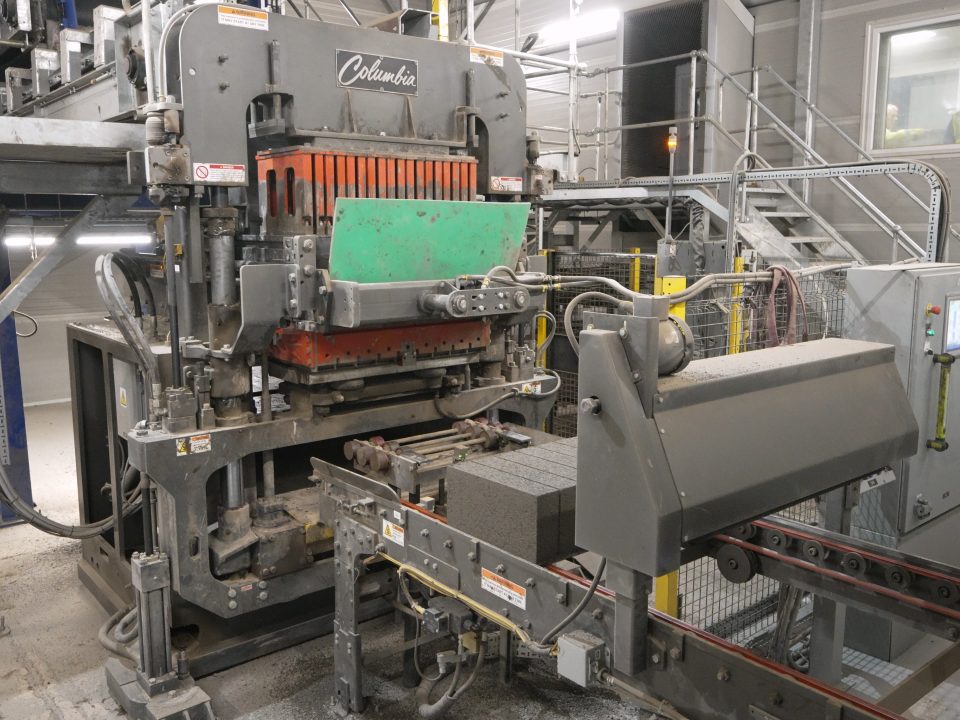

A Columbia 1600 machine with fully automated Columbia pallet handling & versatile product packing using all-electric clamp cubing was finally chosen for their new factory.

A Highly Efficient “State Of The Art” 1600 Concrete Products Plant.

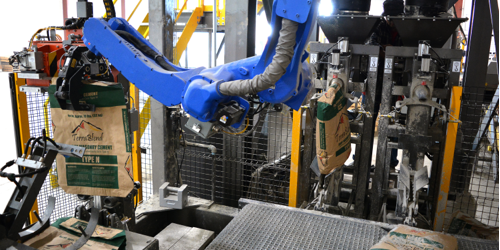

24H capability is perhaps a medium term consideration for WDL. The new plant initially operates at 30,000 UK solid 100mm blocks on a single shift but is fully capable of continuous 24H operation. Designed & constructed by Concrete Batching Systems Ltd in Ireland, a robust set of 6 x 40 tonne segmented aggregate bins will easily facilitate future potential round the clock continuous semi dry concrete mixing. The immediate ground around the plant building has the enormous benefit of an 8 metre raised bank & hence a deep retaining wall was constructed so that aggregate could be stored in bays on the ground at high level & very simply shovel fed, or indeed directly truck tipped, into the batching bin arrangement below. Each bin is complete with highly accurate metering and the batching plant uses weighing & control automation by another Irish firm, Pneutrol International Ltd, who already look after the older Danish static plants on site. Each concrete batch ingredient is, therefore, accurately metered onto a long weigh belt and conveyed to a full batch mix holding hopper directly above the mixer. This ensures there is always a batch of aggregate ready each time the mixer finishes a cycle. A deliberately oversized Teka TPZ 4500 planetary mixer was specified for the plant based on Martin’s own experience of operating his older static plants.

The moisture quality check of material feeding the Columbia 1600 uses the very latest Hydronix moisture system with real-time microwave moisture measurement sensors to sense moisture variation & compensate accordingly. A generous mixed batch holding hopper with a neat reversible belt arrangement was incorporated to convey mix to the feed drawer of the Columbia 1600 machine but also for easy ‘push button’ reverse dump of a mix to outside of the building in the event of any significant stoppage. To complete the batching & mixing scope, two 100 tonne vertical cement silos were erected local to the mixer station to screw convey cement to a weigh vessel above the mixer.

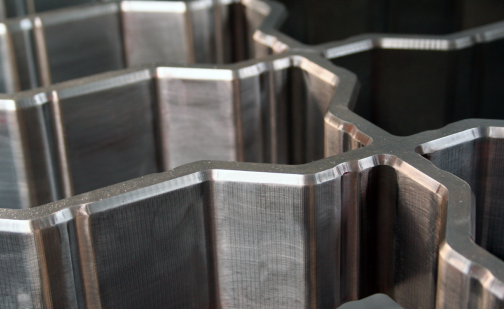

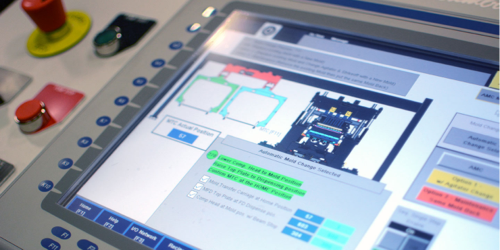

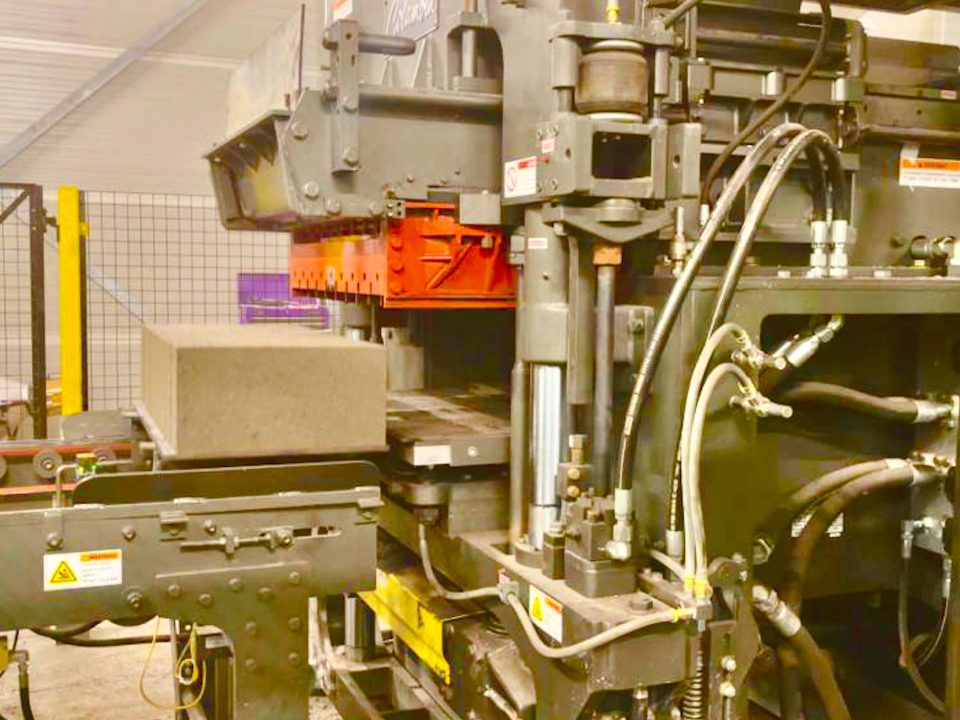

At the heart of the new WDL plant is the Columbia 1600 machine with a flat steel production pallet size of 940x470x10mm for 9 UK blocks per cycle. Chosen largely due to its unique Columbia Vibration Technology (CVT) to provide controlled mould vibration, accurately guided in a completely vertical motion, CVT results in longer mould life, uniform distribution of aggregates, reduced cement usage, precise product heights & product versatility. Columbia’s patented CVT combines over 85 years of innovative engineering and field proven capability to enable the highest quality and widest range of products in the world. The 1600 is an easy to operate machine with extremely user friendly Allen Bradley Command View remote machine control.

Martin Lewis was meticulous in the design of his plant to include a generous sound room with separate hydraulic pump room local to the machine. Attached to the sound room is a separate, air conditioned, operator control room raised a few metres from factory floor. The operators have a fantastic view of the pallets coming towards them and under their feet as they observe through deep panes of full height acoustic glass.

Designed into the new factory building there is a dedicated mould workshop for rebuild of genuine Columbia moulds, fully fitted out with crane and precision machined surface table to allow off-line alignment of mould shoes with die cavities. Moulds are routinely inspected, oiled and stored after use and will be overhauled in

the new workshop.

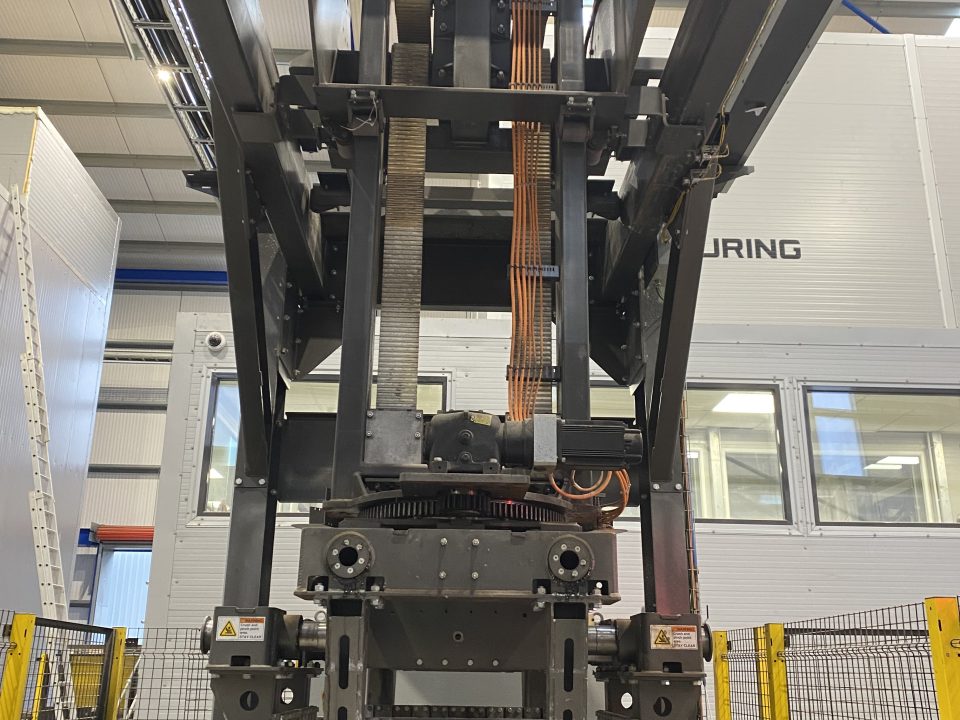

The green product from the Columbia 1600 machine is gently conveyed along smooth urethane belt conveyors to a stacker where 4 pallets of product per shelf are elevated to 14 shelves high & to a maximum combined pallet & product payload of just over 11 tonnes (25,000 lbs). The load is then collected by the PTS up-car and brought onto the lo-car for turntable rotation and transport to the correct location in the fully automatic curing chamber sequence. The precise, galvanized mild steel curing chamber holds over 10,000 production pallets and is again designed for continuous 24H operation and reduced cement usage. Heavy duty lo-car & up-car rails were mitered and then staggered to ensure smooth & gentle transition of the car wheels throughout the curing chamber.

A single atmosphere, fully temperature & humidity controlled chamber with all round air circulation was designed and built by Kraft in Germany, to ensure completely even curing conditions. The roof and walls of the kiln were built with increased thickness insulation panels with care taken to fully eliminate thermal bridges & so prevent any local condensation.

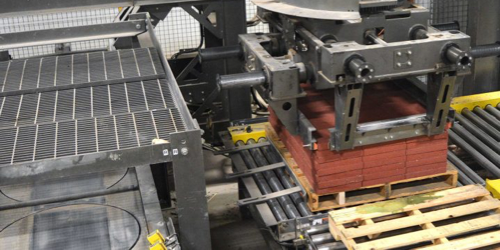

Upon exiting the curing chamber on the dry side conveyor line, product is removed from the production pallet (2 pallets at a time) by an “all electric” Columbia block cuber, before the empty pallets are then conveyed through a pallet scraper & brush to remove any fine debris & turned over to even out the vibration through the production pallet on the next machine cycle. The steel pallet is finally coated with a gentle mist of oil before entering a pallet accumulator at the back end of the 1600 block machine.

Each cube of product is built either directly onto a heavy duty slat conveyor or onto a wooden transport pallet. Wood pallets are dispensed from an automatic magazine when required and the cube of block is then horizontally strapped before exiting the factory.