Batching & Mixing

Cutting-edge automation, precisely engineered batching solutions, industry-leading line of mixers.

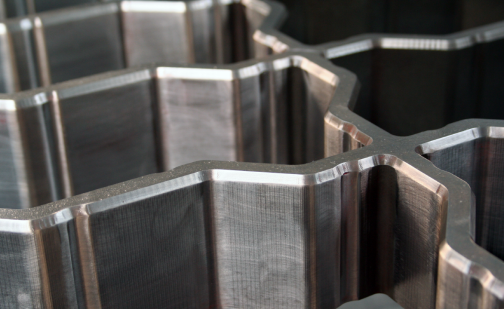

Mixers

Mixers are at the core of every plant. We offer a wide variety of durable, low-maintenance, easy-to-operate mixers to suit every need.

Batching Controls

Our automation systems ensure consistency among your concrete products and will keep your line running smoothly.

Material Handling

A full range of concrete delivery products for precast, pipe, block, wall panel, paver, SWR and other concrete related production.

Quality Mixers

Mixers are at the core of every concrete plant. We offer a wide variety of durable, low-maintenance, easy-to-operate mixers to suit every need.

Planetary Mixers

The family of Techmatik SPM planetary mixers ensures fast mixing cycles for each kind of concrete by using a washing system with the initial water dosing. Precise mixing of concrete is achieved by the application of the optimal number of mixing blades. The high-speed rotor provides a high degree of concrete mix homogenization.

Brochure DownloadSPM-375

Input / Output

Input

375 l

Input Weight

600 kg

Output

.25 cu meter

Mixer Specs

Driving Power

9.2 kW

# Mixing Stars

1

# Mixing Blades

2

SPM-500

Input / Output

Input

500 l

Input Weight

820 kg

Output

.33 cu meter

Mixer Specs

Driving Power

11 kW

# Mixing Stars

1

# Mixing Blades

2

SPM-750

Input / Output

Input

750 l

Input Weight

1200 kg

Output

.5 cu meter

Mixer Specs

Driving Power

2 x 9.2 kW

# Mixing Stars

1

# Mixing Blades

2

SPM-1125

Input / Output

Input

1125 l

Input Weight

1800 kg

Output

.75 cu meter

Mixer Specs

Driving Power

2 x 15 kW

# Mixing Stars

1

# Mixing Blades

2

SPM-1750

Input / Output

Input

1750 l

Input Weight

2800 kg

Output

1.15 cu meter

Mixer Specs

Driving Power

2 x 22 kW

# Mixing Stars

2

# Mixing Blades

4

SPM-2250

Input / Output

Input

2250 l

Input Weight

3600 kg

Output

1.5 cu meter

Mixer Specs

Driving Power

2 x 30 kW

# Mixing Stars

2

# Mixing Blades

4

SPM-3000

Input / Output

Input

3000 l

Input Weight

4800 kg

Output

2 cu meter

Mixer Specs

Driving Power

2 x 37 kW

# Mixing Stars

2

# Mixing Blades

4

SPM-3750

Input / Output

Input

3750 l

Input Weight

6000 kg

Output

2.5 cu meter

Mixer Specs

Driving Power

2 x 55 kW

# Mixing Stars

2

# Mixing Blades

6

Rotating Pan Mixers

The Columbia Rotating Pan Mixer offers a cost effective, counter-current mixing action with multiple agitation stars; mixing at different velocities. The mixer comes with a number of agitator designs specifically supplied for the type of concrete that is to be produced. A long term standard in pipe applications, the self-sealing discharge door makes it a perfect mixer for the more technical and fluid SCC mixes.

RP 60

Output Specs

Yield

6000 lbs

Pan Volume

Top of Liners

111 cu. ft

Total

121 cu. ft

RP 80

Output Specs

Yield

8000 lbs

Pan Volume

Top of Liners

154 cu. ft

Total

168 cu. ft

RP 100

Output Specs

Yield

10,000 lbs

Pan Volume

Top of Liners

180 cu. ft

Total

216 cu. ft

RP 120

Output Specs

Yield

12,000 lbs

Pan Volume

Top of Liners

198 cu. ft

Total

240 cu. ft

Twin-Shaft Mixers

Our twin-shaft mixers feature a very fast, compulsory mixing action well suited for high volume concrete applications where volume, concrete strength and speed are paramount in the plant design. The twin-shaft mixers can handle a large variance of aggregate sizes up to a couple of inches in diameter. These mixers come with a number of options including a high pressure washout system.

LIEBHERR DW 4.5

Capacity

Normal

6 cu. yards

Filling

9 cu. yards

Mixer Specs

3-Phase Motor

2x100 HP

Voltage/Frequency

460/60Hz

Mixer Rotating Speed

20.7 RPM

Peripheral Speed

5.3 ft/s

Weight of Standard Version

12.7 tn

LIEBHERR DW 6.0

Capacity

Normal

8 cu. yards

Filling

12 cu. yards

Mixer Specs

3-Phase Motor

2x150 HP

Voltage/Frequency

460/60Hz

Mixer Rotating Speed

20.7 RPM

Peripheral Speed

5.9 ft/s

Weight of Standard Version

20.9 tn

Ribbon Blade Mixers

The Columbia Ribbon Blade mixers supply an excellent blend of concrete through a time tested and proven folding mixing action. The Columbia mixers offer a cost effective and durable mixer design with a proven 25 year lifespan. The Columbia mixers are easy to operate, easy to maintain and yield excellent concrete for a large range of products.

Model 30

Capacity

Output Volume

30 cu. ft

Mixer Specs

Motor

20 HP

Width

111"

Hopper Width

69"

Height

48"

Weight

7250 lbs

Model 54

Capacity

Output Volume

54 cu. ft

Mixer Specs

Motor

50 HP

Width

145.75"

Hopper Width

85.5"

Height

64"

Weight

15,500 lbs

Model 81

Capacity

Output Volume

81 cu. ft

Mixer Specs

Motor

2x40 HP

Width

174.5"

Hopper Volume

96"

Height

72"

Weight

19,200 lbs

Model 108

Capacity

Output Volume

108 cu. ft

Mixer Specs

Motor

2x60 HP

Width

170.5"

Hopper Width

84"

Height

92"

Weight

27,500 lbs

Model 135

Capacity

Output Volume

135 cu. ft

Mixer Specs

Motor

2x75

Width

197"

Hopper Width

109"

Height

92"

Weight

32,600 lbs

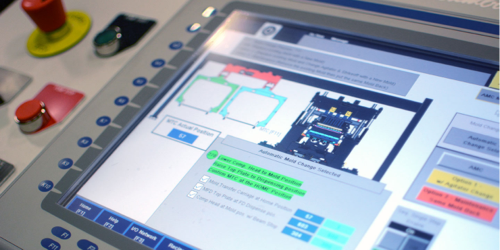

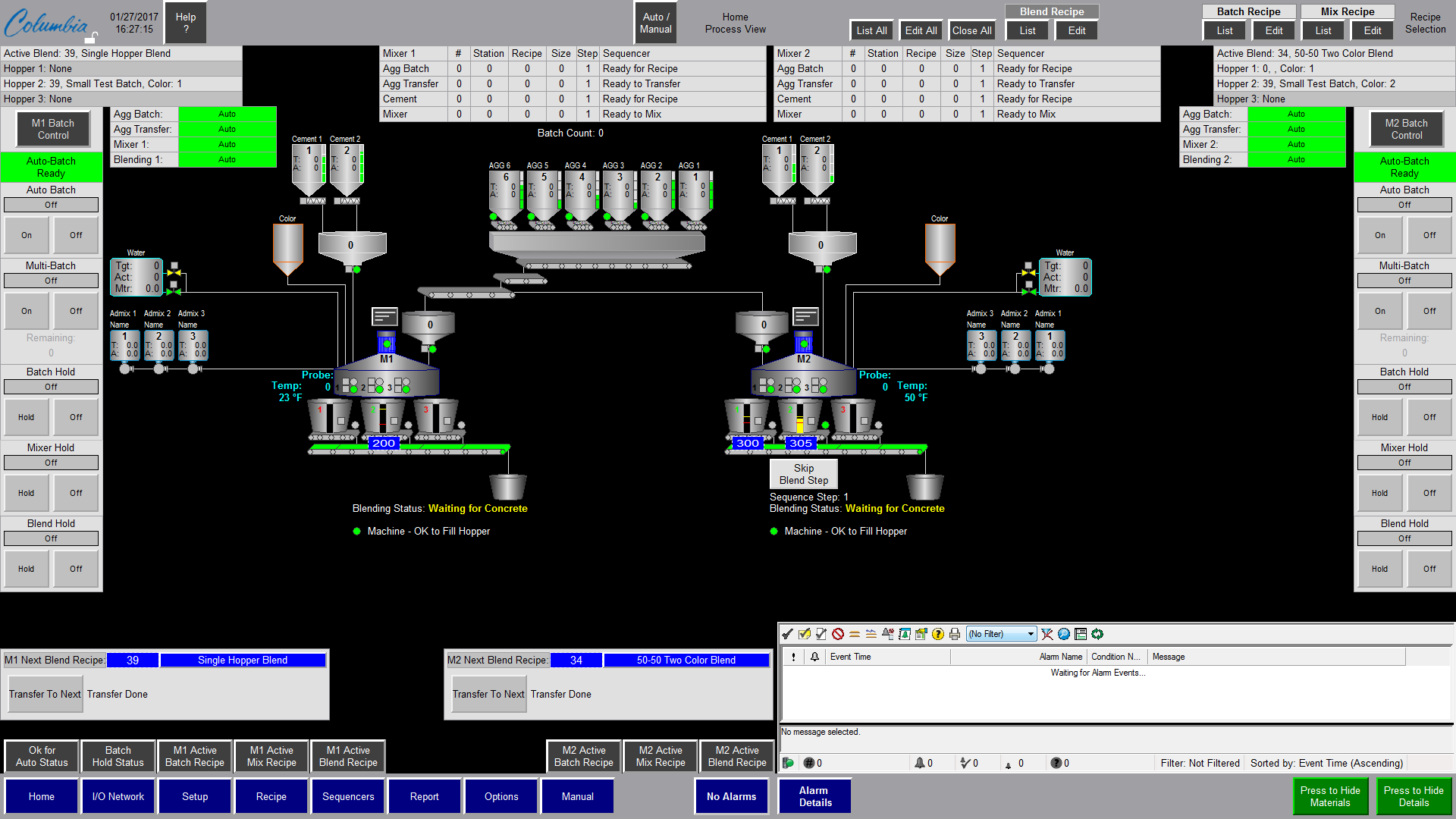

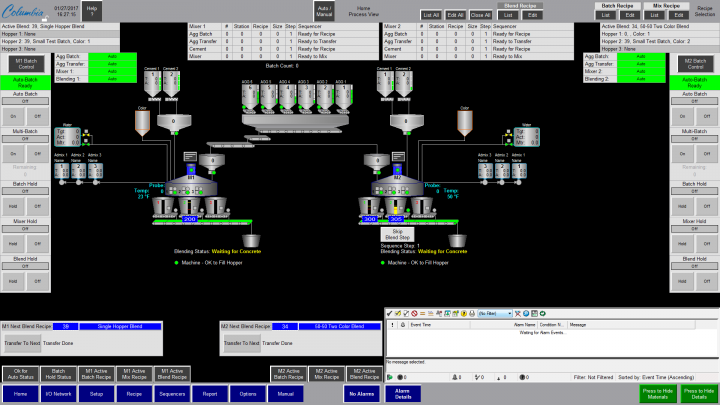

Batching Controls

Columbia offers a full range of batching control systems to meet the demanding requirements of today’s concrete industry. All of our industry-leading controls include the latest technology including: graphical user interface that is easy to operate, CompactLogix PLC and PanelView Plus HMI for optimal performance and prewired controls cabinet to reduce installation time and costs. Whether you operate a small masonry plant or a multiple mixer Precast operation, Columbia Machine has a safe and reliable batching controls solution to fit your needs.

Features

- Easy to use batch and mix recipe designer

- Graphical sequencer for mix optimization

- Pop-up screen navigation for easy set up of controls

- Volumetric and weighed aggregate batching

- Scalable system for single and multiple mixer operations

- Colored concrete blending recipes

- Multiple safety zone control

- SQL database with web access for recipes and records

- Remote operation through smart tablet devices

- Retrofits into existing batch plants

- 24/7 service

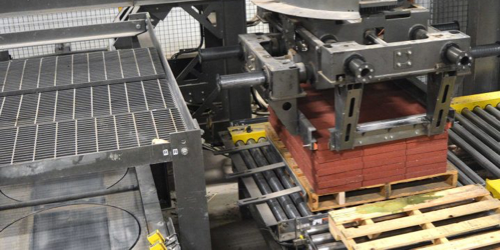

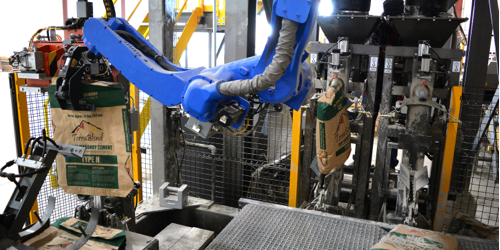

Material Handling

Columbia Batching Solutions offers a complete line of aggregate bins, conveyors, truck hoppers, delivery systems and electronics to meet almost any aggregate handling requirement.

- Aggregate systems

- Cement systems

- Admix and color systems

- Concrete delivery

We’re Ready To Help

For more information or questions on any of our concrete products solutions