Columbia Vibration Technology

Columbia's patented vibration technology (CVT) combines field-proven designs with industry-leading manufacturing capabilities, enabling producers to create a wide range of high-quality products.

Cement Usage

Equal compaction of material translates to less cement usage and lower costs.

Product Density

More uniform product density for increased product strength and aesthetics.

Mold Life

CVT reduces mold wear, resulting in longer mold life and reduced production costs.

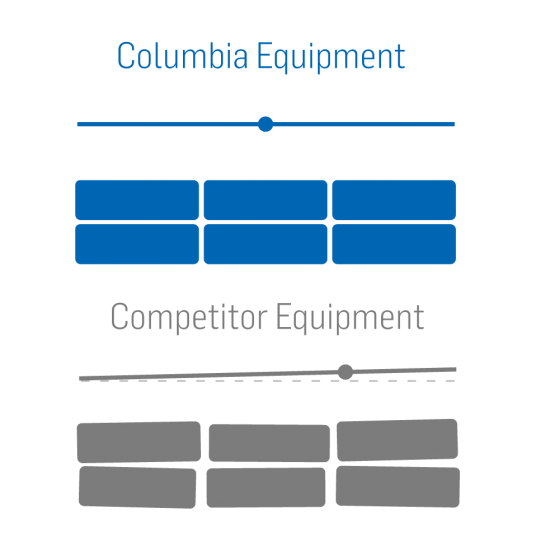

Height Control

Industry leading product height control, regardless of production pallet thickness.

Simply put - CVT makes you money. Here's how:

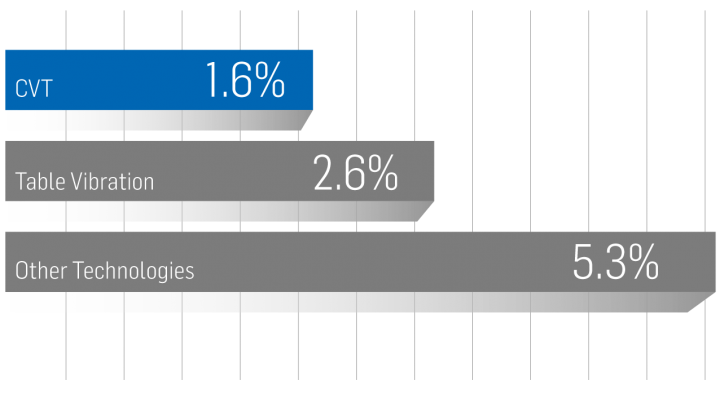

CVT - Know The Difference

True vertical vibration provides:

even density through the product

less cement use

lower mold wear

Table Vibration

Impact bars from the bottom of the mold leads to:

poor height control

uneven product density

increased cement use in tall products.

Other Mold Vibration

Rocking motion of mold creates:

uneven product density

increased cement consumption

higher mold wear.

Vibration Technology Explained

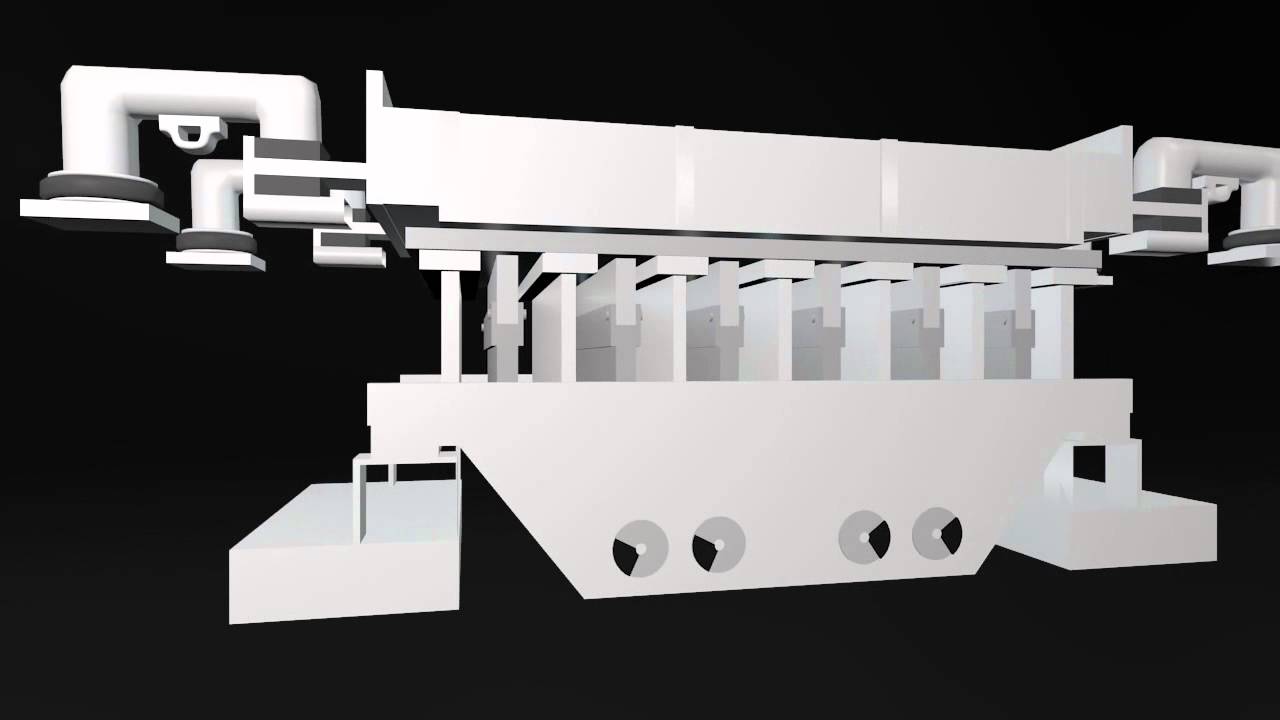

Columbia Vibration Technology

Columbia's patented vibration technology, CVT, combines over 80 years of innovative engineering and field proven designs with industry leading manufacturing capabilities. CVT enables producers to create the highest quality and widest range of products in the world.

Table Vibration

Table vibration is commonly found on big board or large pallet concrete products machines. It uses vibrators which are connected to impact bars, these bars strike the bottom of the production pallet to create vibration throughout the product. It is inherently inefficient due to the random motion, which leads to poor height control and non-linear product densities & textures.

Other Vibration

Other mold vibration is a style of vibration for concrete products machinery where the vibrators are attached directly to the mold. Because of how these vibration systems work, there is an induced rocking motion caused by out-of-sync vibrators. This motion leads to uneven product densities and overall weak concrete products with inconsistent textures and high mold wear.

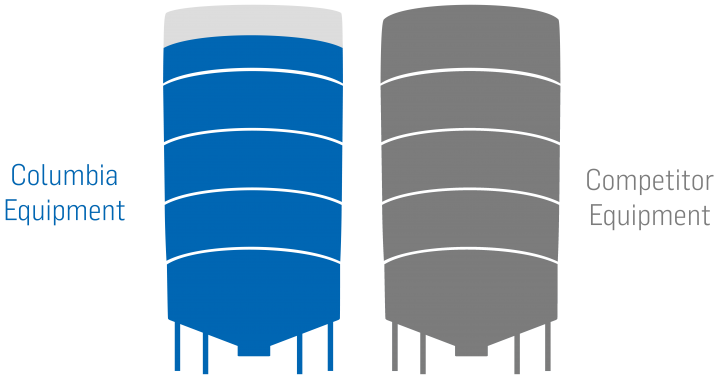

70% More Uniform Density

An independent lab study proves that utilizing CVT provides up to 70% more uniform product density from top-to-bottom and across the production pallet when producing concrete products on a Columbia Machine. This not only makes for a stronger product, but demonstrates the cement savings CVT offers. Less cement usage means less cost, which ultimately leads to higher profits.

10% Less Cement

With CVT the mold vibration forces are completely uniform top to bottom and across the production pallet. That provides equal compaction of material throughout the entire product and the ability to use less cement compared to other vibration systems.

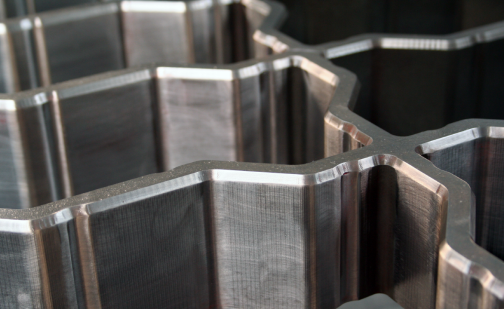

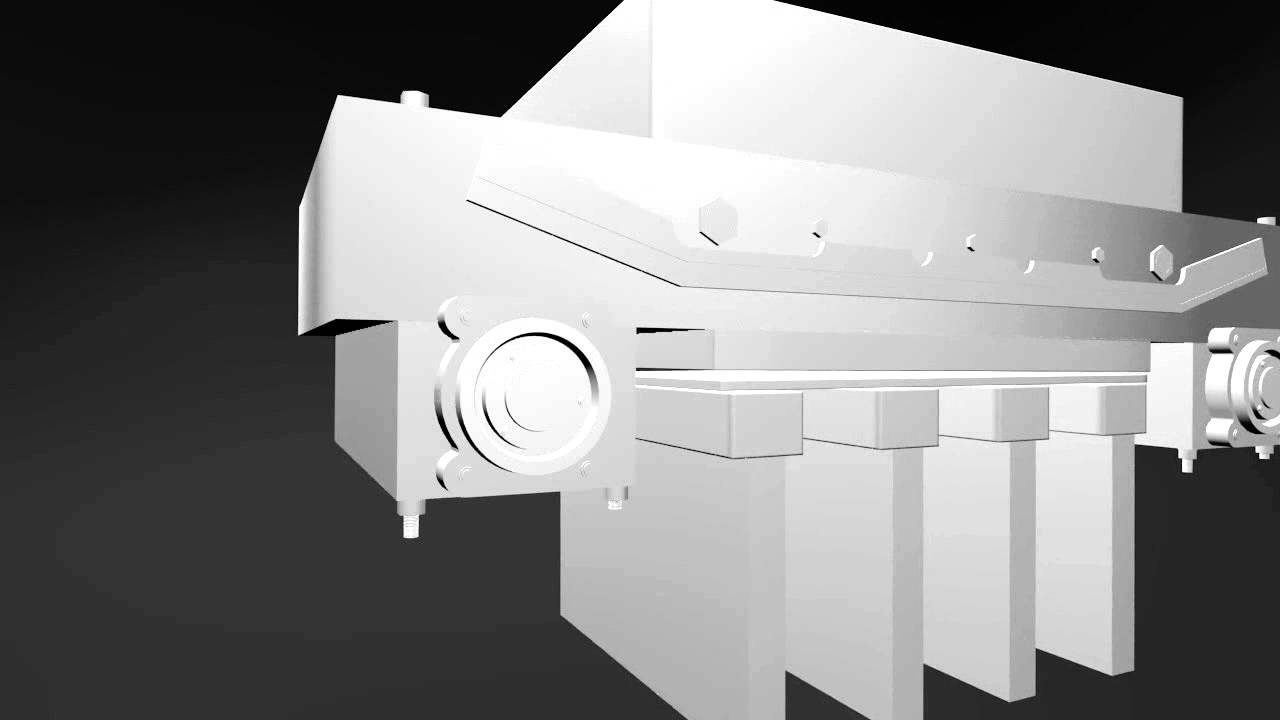

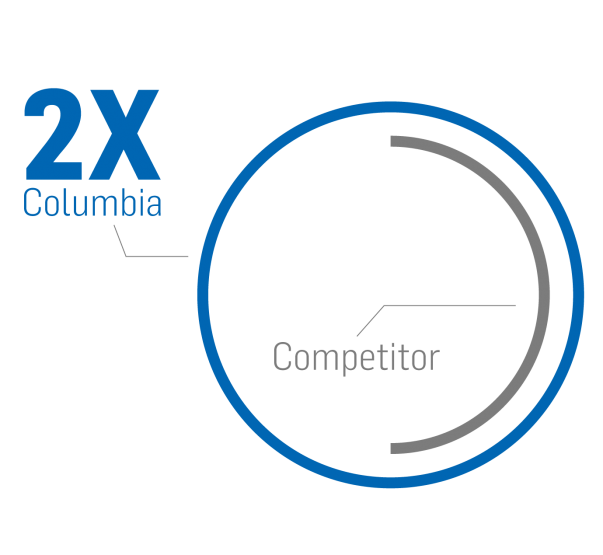

2X Extended Mold Life

The true vertical vibration provided by CVT means reduced friction between the shoes and the mold compared to other mold vibration systems. Less mold wear means longer mold life and more money in your pocket.

Same materials, same mix designs, same product… same overall general conditions, but dramatically different results.

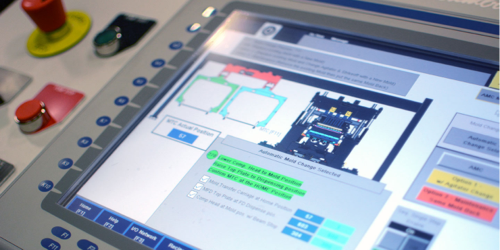

Precision Height Control

CVT offers producers the ability to control the height of their product like no other technology. This precision allows the mason or landscape contractor to lay product faster and more enjoyably in comparison to working with uneven products – but, it also means less material waste for you as the producer. Less waste means more money saved.

We'Re Ready To Help

For more information or questions on any of our concrete products solutions